Turbocharging and Supercharging

A turbocharger is a device that increases the horsepower by compressing the intake air before it enters the engine.

Turbocharging can be done in two ways:

- A supercharger relies on an engine-driven air pump or compressor

- A turbocharger relies on a turbine driven by the engine's exhaust gases

Turbochargers

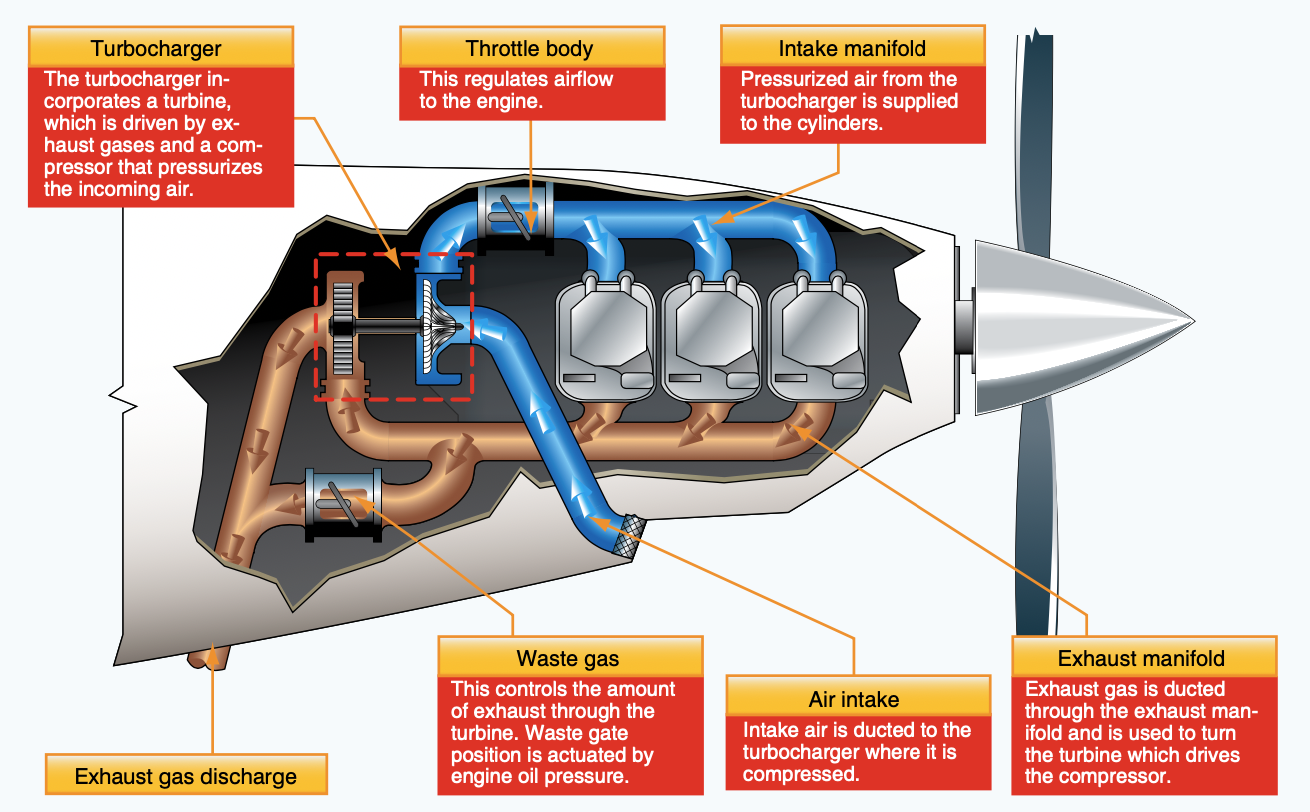

Turbochargers utilize a turbine which is powered by the engine's exhaust gases. This turbine is used to drive a compressor which compresses the engine's intake air, which allows the engine to burn more fuel and produce more power.

Since air density decreases with altitude, turbochargers can be used to get sea-level-like performance at high altitudes.

Components

- Turbine: Driven by the engine's exhaust gases

- Compressor: Connected to the turbine by a shaft, compresses the intake air

- Wastegate: Controls the boost pressure by limiting how much air bypasses the turbine

- Intercooler: Cools the compressed air before it enters the engine, only in some turbocharged engines

Types of Turbochargers

- Altitude turbocharging or turbonormalizing: Used to maintain sea-level performance at high altitudes

- Ground boosting: Compresses intake air to pressures higher than sea level to increase power output

The type of turbocharging system depends on the engine's rating.

Types of Wastegates

- Automatic waste gate: Uses a linkage to the throttle to control the boost pressure, or a engine-oil pressure actuator

- Manual waste gate: Controlled by a separate control in the cockpit

- Fixed waste gates: The waste gate is fixed to a certain bypass configuration. Care must be taken to ensure that the engine does not overboost.

Overboosting

Overboosting occurs when the turbocharger produces more boost pressure than the engine can handle. This can cause detotation and engine damage.

This can occur in a manual waste-gate system if the waste gate is not opened while descending from a high altitude.

It is also important for engine oil to be at the correct temperature before applying takeoff power. The turbine can spin as high as 80,000 RPM, so the bearings in the system must be continuously lubricated by engine oil.

Critical Altitude

The critical altitude is the altitude at which the turbocharger can no longer maintain sea-level-like performance. This is the point at which the turbine can no longer compress the air to sea-level density.