Constant-Speed Propellers

Constant-speed propellers are a type of propeller that can change pitch to maintain a constant RPM. This allows the engine to operate at its most efficient RPM for a given flight configuration.

Components

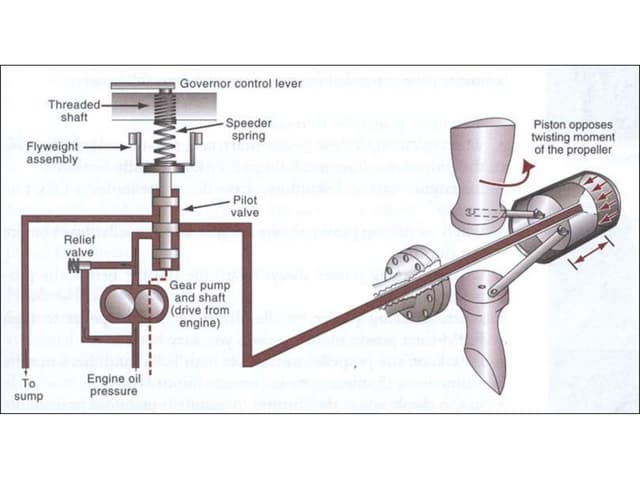

Changing the pitch of the propeller is accomplished by a governor, which is housed in the spinner.

The governor uses a combination of flyweights and springs to regulate how much oil should be let into the propeller hub.

- When the engine RPM increases, the flyweights move outward, which opens a valve and oil flows into the the propeller hub. This causes the propeller blades to flatten out, decreasing the pitch and reducing the engine RPM.

- When the engine RPM decreases, the flyweights move inward, which opens the valve and oil flows out of the propeller hub. This causes the propeller blades to increase pitch, increasing the engine RPM.

Operation

The constant-speed propeller is controlled by the propeller control lever in the cockpit. The propeller control lever is connected to the governor by a series of linkages.

- Moving the propeller control in increases the RPM by increasing the pitch of

the propeller blades.

- This is typically used for takeoff and climb when you want to maximize thrust and RPM.

- Moving the propeller control out decreases the RPM by decreasing the pitch of

the propeller blades.

- This is typically used for cruise when you want to maximize fuel efficiency.

Loss of engine oil pressure

If a loss of oil pressure occurs, most airplanes will fail into the low pitch position. This is because the governor is spring-loaded to return to the low pitch position if oil pressure is lost.